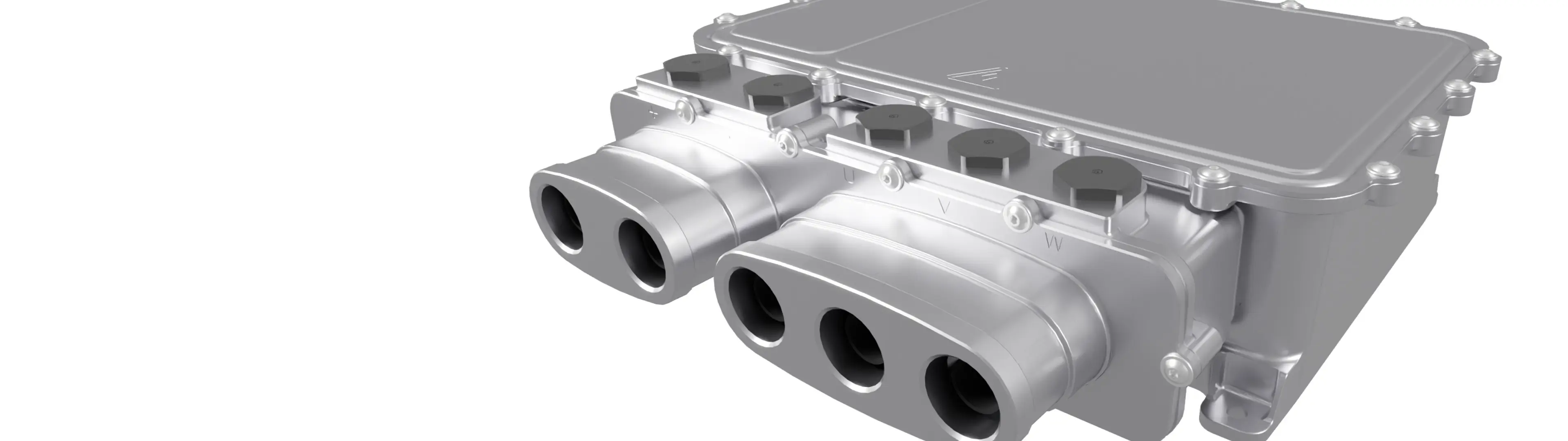

IPG5

IPG5 800V Silicon Carbide Integrated Inverter

800V Silicon Carbide Inverter for faster charging, higher efficiency, longer range.

The hybrid and electric vehicle (EV) market is both growing and evolving rapidly. Improving powertrain efficiency is key to competitiveness. EV charging infrastructure is changing and improving, however charge anxiety, range anxiety and cost remain the common concerns for consumers.

To address these challenges, Motion Applied has developed a next generation, 800V Silicon Carbide (SiC) inverter platform. 800V offers faster vehicle charging speeds and Silicon Carbide technology provides higher powertrain system efficiency and greater vehicle range and performance. The benefits of adopting Motion Applied’s inverters into OEMs’ products are as follows:

- OEMs can mitigate customer's charge anxiety by leveraging ultra-fast charging stations to cut charge times.

- OEMs can mitigate customer's range anxiety by increasing their vehicle range by >7%.

- OEMs can decrease their vehicle costs and weight through overall powertrain system optimisation.

Documents

The next step in electrification

Innovation in the fast-moving automotive space means meeting today's questions with tomorrow's answers. Motion Applied's 800V Silicon Carbide inverter responds to a current challenge with a future-proof solution for both established and new entrant OEMs.

Motion Applied have a proven track record of pioneering high-performance inverters in automotive, leveraging the highest echelons of motorsport to fast-track development and then bringing that learning back into automotive with class-leading performance.

Our Silicon Carbide inverter has the highest frequency switching rate that is currently possible and is 800V compatible. This means faster power transfer and a lighter system compared to 400V inverters. This allows OEMs to develop vehicles with greater ranges, faster charging times and better acceleration, at a comparable cost.

OEMs that are using existing 400V infrastructure have the option to use Motion Applied's inverter at 400V with the ability to upgrade it to 800V at a later date. That means an OEM can bring 800V vehicles to market while utilising the existing investment in 400V technology, spreading the cost across a wider set of vehicles.

Silicon Carbide technology

Motion Applied's new inverter uses Silicon Carbide technology, which enables a significant increase in switching frequency. By achieving class-leading switching frequencies, our inverter allows the use of a more efficient and lightweight drivetrain; including inverter, motor and battery systems. Silicon Carbide inverters offer considerable efficiency gains versus conventional inverters because they produce less heat and, therefore, have lower cooling demands.

The new inverter also occupies a smaller form factor, with our motorsport experience enabling us to achieve class-leading power density, making it ideal for use in high-performance or package-constrained applications. Increased efficiency and reduced mass means greater range and improved performance. Smaller and lighter models need less energy to drive them. Combined with the increased drivetrain efficiency, this enables a reduction in battery size - typically the most expensive single component in a battery electric vehicle.

For systems integrators, our caseless inverter variants provide only the core hardware, which means maximum flexibility in packaging an off-the-shelf component into a custom system. This is a cost-effective contrast to conventional inverters.

Key benefits

In summary, Motion Applied's 800V Silicon Carbide inverter has the following benefits:

- Faster Charging: Able to deliver the next generation of electric vehicles utilising 800V for ultra-fast charging capability

- Increased Range: Through reduced heat production and higher frequency switching, the Silicon Carbide technology allows optimisation of the entire powertrain system: a lighter, more efficient inverter with reduced cooling requirements, smaller, lighter and higher speed motors that run more efficiently and lighter 800V cabling maximise range for a given battery capacity

- Reduced Cost: As well as lower cost motor opportunities enabled by downsizing to a higher speed motor for the same power output, instead of leveraging the inverter system benefits for more range, the efficiency gains can instead be utilised to downsize the battery, the single most expensive component in the vehicle, whilst maintaining range

- Improved Packaging: Unrivalled power density, a result of our experience in motorsport, means that the compact, lightweight, high-performance design combined with optimised cooling minimises integration challenges

- Flexibility: Clear upgrade path from 400V infrastructure to 800V to maximise existing investments and spread cost across a wider set of vehicles. Ability to offer a caseless variant for maximum integration flexibility.